MAN Energy Solutions

MAN Energy Solutions is one of the world’s leading suppliers of large diesel and gas engines and turbomachinery. With headquarter in Germany, MAN Energy Solutions employs over 14 000 people with 120 service locations worldwide.

We are proud that we were able to simplify the processes for the four-stroke division of MAN Energy Solutions with our processes easier with our software.

Start of the collaboration with B&W Software

The collaboration between MAN Energy Solutions ( then MAN Diesel & Turbo) and B&W began in 2013.

The problem – making complex models configurable nevertheless

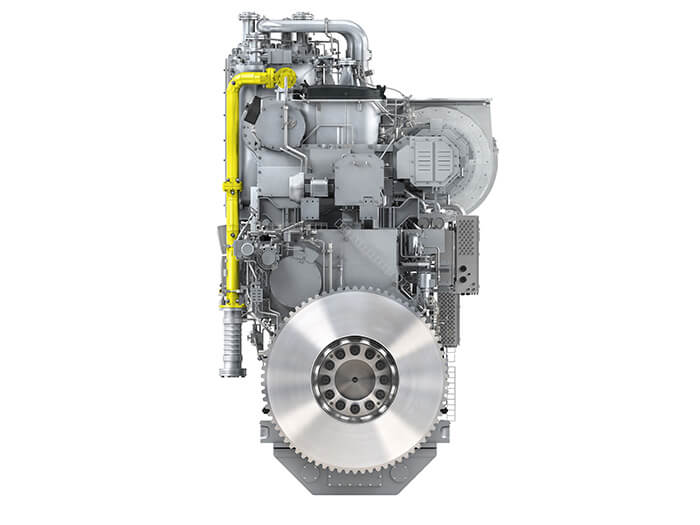

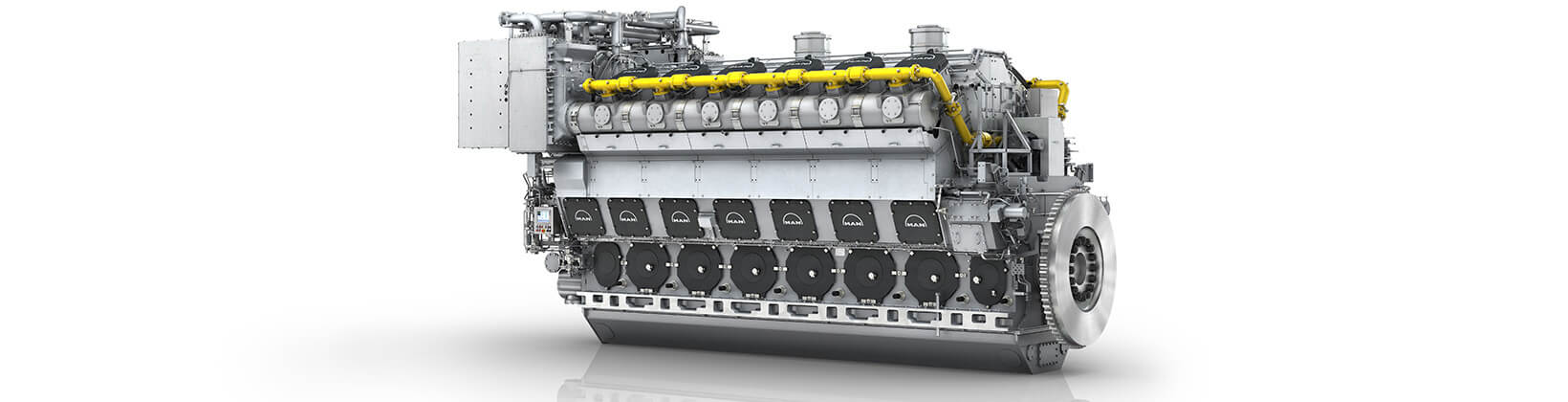

A four-stroke diesel engine at MAN Energy Solutions consists of approx. 6000-8000 different Creo models, most of which are installed several times.

In addition, issues such as complex edge geometry, external assignments to design service providers, the representation of the entire engine in so-called installation drawings with information details for installation at the customer, etc. play an important role.

The provision of simplified Creo models is therefore a “must have” to reduce loading times and increase performance in the daily design process. Last but not least, this topic has also become particularly topical in view of the sometimes low bandwidth in the home office. The demands placed on the simplified models are due to the up-to-dateness and inherited metadata such as mass properties of their original assemblies.

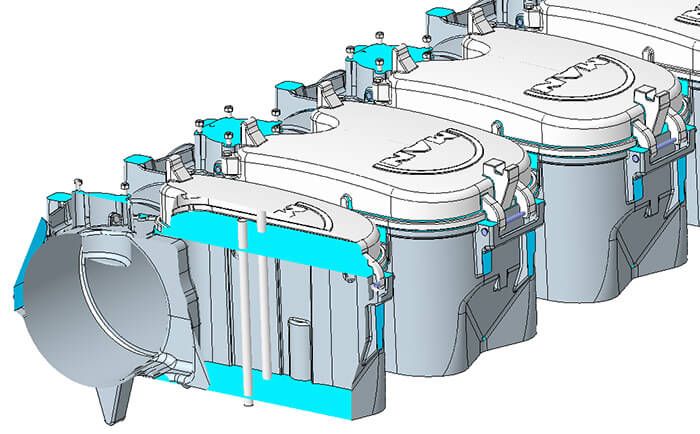

A further requirement is the ‘obscuring’ of geometries that are particularly worthy of protection in order to be able to make the models available to external users and customers.

The Solution – Multifunctional Shrink Wrap Models

One building block for a lean, easy-to-edit, yet configurable overall engine model in Creo is simplified components, such as shrinkwraps of the main assemblies.

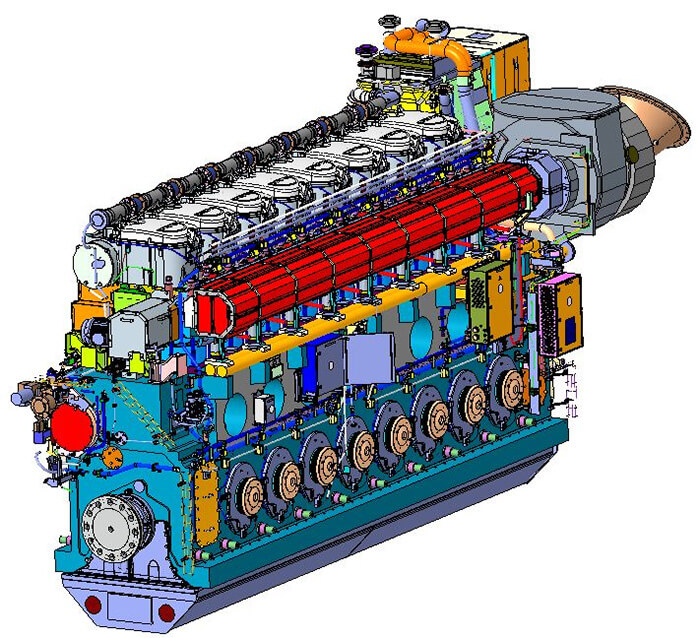

At MAN Energy Solutions, as part of the DMU (Digital Mock-Up) design process, models of the main assemblies are automatically converted to JT format both when they are created and modified.

Together with B&W Software, a method was developed to derive shrinkwrap models in addition to the JT files, which not only represent the geometric representation of the assemblies, but also perform a number of other functions.

- The shrinkwrap models are automatically checked in to Windchill and are thus always in sync with the main assemblies on a daily basis.

- Important metadata from the main assemblies is transferred.

- The mass properties (weight, center of gravity, inertia tensor) of the original model are determined during conversion and transferred to the shrinkwrap model.

- Component parameters such as the above-mentioned shipyard connections including the visualization of the media flows are transferred to the shrinkwrap models.

- The designer can have IP-relevant geometries hidden individually and automatically.

Conclusion

The multifunctional shrinkwraps at MAN Energy Solutions are extremely versatile: As lightweight edge geometry in assembly drawings, for overall engine models in installation drawings, as environment geometry for development partners, etc.

B&W Software developed not only the advanced conversion routine used on the conversion server, but also the user interface for users to set both the shrinkwrap parameters and the geometry subject to IP protection.