Mechanical, Plant Engineering and Equipment Manufacturing

From a technical point of view, the two terms do not fit together ideally, but from the point of view of our software products there are some similarities.

Production equipment engineering is about the planning, design and manufacture of devices that are required in the production, assembly or testing of a wide variety of products. This mostly involves the handling, transport and storage of components and assemblies in the manufacturing process.

Plant engineering refers to a wide range of technical industries, such as process engineering, power engineering, or mechanical engineering. In the process, technical components are combined to form a complete system with precisely defined tasks.

An order in plant engineering is usually a one-off project, which can be distinguished from industrial series and mass production. It passes through various phases, from the preliminary clarification and quotation phase to execution and evaluation.

In both cases, the construction of the structures in question often requires a supporting structure, which is preferably made of standardized elements in order to keep costs low. In the course of this, the individual components of the plant or equipment must also be connected to each other, again using low-cost standard connecting elements wherever possible.

How to automate profile design?

To support this process in the design phase, we have developed the Advanced Framework Extension, a module that is fully integrated in Creo Parametric. This allows the tasks of a classic profile design to be significantly accelerated or automated. An extensive library of profile cross-sections and connecting elements can be accessed and the subsequent documentation automatically derived.

Outside of pure profile design, you can also access the independent library for screw and pin connections (Intelligent Fastener Extension), which is also integrated in Creo Parametric. Using a separate user interface, the standard parts can be easily assembled and the necessary cutouts automatically generated.

-

Advanced Framework Extension

Advanced Framework Extension (AFX) supports you in creating profile assemblies of steel profiles, aluminum-profile systems or other user-defined profiles.

More

In the further process flow of the design, further software tools in the area of documentation offer a reduction in workload. This can be the automatic derivation of associative hole tables (SMARTHolechart), or assistance in applying hatching to large assembly drawings (SMARTXHatch), which accelerates or automates very time-consuming subtasks during drawing derivation.

Color coding of individual components or component surfaces for documentation or communication can also be helpful and useful. In order to perform this task as safely and quickly as possible, we offer SMARTColor, a tool that largely automates the task of color assignment based on a set of rules.

Products

-

SMARTHolechart

SMARTHolechart

SMARTHolechart relieves you of the hours of work involved in adding drilling information and offers intelligent creation of hole charts. Rotational geometries are recognized automatically and hole types can be classified individually.

More -

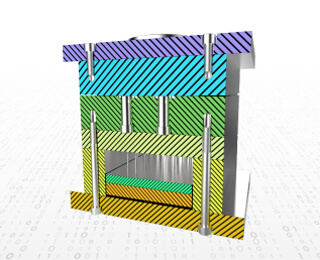

SMARTXHatch

SMARTXHatch

Easily define X-hatch properties within assembly drawings and update only with just a single push on the button! Especially in your drawings of large tool assemblies, SMARTXHatch speeds up your cross-hatching definition of section views significantly.

More -

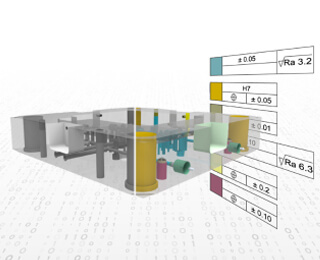

SMARTColor

SMARTColor

SMARTColor helps you to provide machine-readable product and manufacturing information (PMI) through the rule-based application of predefined colors.

More -

Advanced Framework Extension

Advanced Framework Extension

Advanced Framework Extension (AFX) supports you in creating profile assemblies of steel profiles, aluminum-profile systems or other user-defined profiles.

More -

Intelligent Fastener Extension

Intelligent Fastener Extension

Intelligent Fastener Extension (IFX) allows you to handle screws and pins in your profile construction easily. You can define the dimensions and drill holes in an intuitive dialog.

More